Tolerances

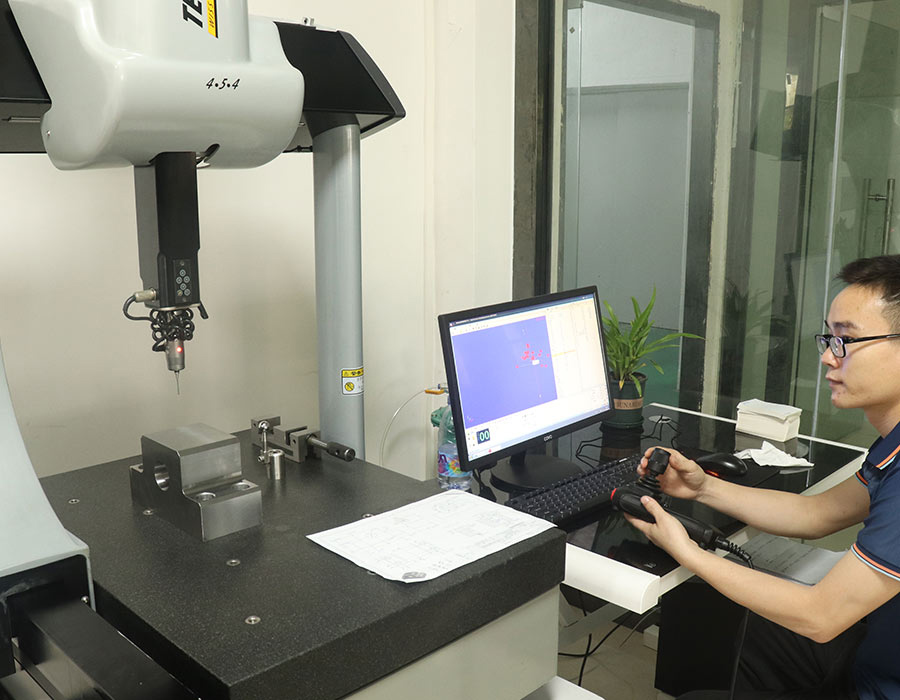

Our commitment to quality is evident in our standard tolerance of 0.005mm. This level of accuracy is ideal for applications requiring tight tolerances, such as medical devices, automotive components, and scientific instruments.

Metal stamping, also known as metal pressing or sheet metal stamping, is a manufacturing process that involves the use of a stamping press to shape and form metal sheets or coils into desired parts or components. This process is widely used across various industries, from automotive and aerospace to consumer electronics and home appliances, to create a diverse array of products.

In metal stamping, a metal blank or sheet is placed into a stamping die, which is a specialized tool designed to impart the desired shape or form to the metal. The stamping press then applies immense pressure to the metal, forcing it to conform to the shape of the die. This process can be repeated multiple times to achieve the final desired part or component.

The metal stamping process typically involves several key steps:

There are several different types of metal stamping processes, each with its own unique characteristics and applications:

Metal stamping offers several key advantages over other manufacturing processes:

While metal stamping offers many advantages, there are also some potential drawbacks to consider:

Metal stamping can be performed on a wide range of metal materials, each with its own unique properties and characteristics:

Metal stamping is used to produce a wide range of parts and components across numerous industries, including:

When selecting a metal stamping service provider, there are several key factors to consider:

When it comes to metal stamping, you have two main options: custom metal stamping and standard metal stamping.

|

|

|

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

The choice between custom and standard metal stamping will depend on your specific part requirements, production volume, and budget.

Metal stamping is a versatile and efficient manufacturing process that has become an essential tool in the production of a wide range of parts and components. By understanding the key aspects of metal stamping, including the different processes, materials, and applications, you can make informed decisions about the best approach for your specific needs.

If you're looking to explore the benefits of metal stamping for your next project, I encourage you to reach out to a reputable metal stamping service provider. They can provide expert guidance and support to help you navigate the process and achieve the best possible results. Don't hesitate to contact them today to learn more!

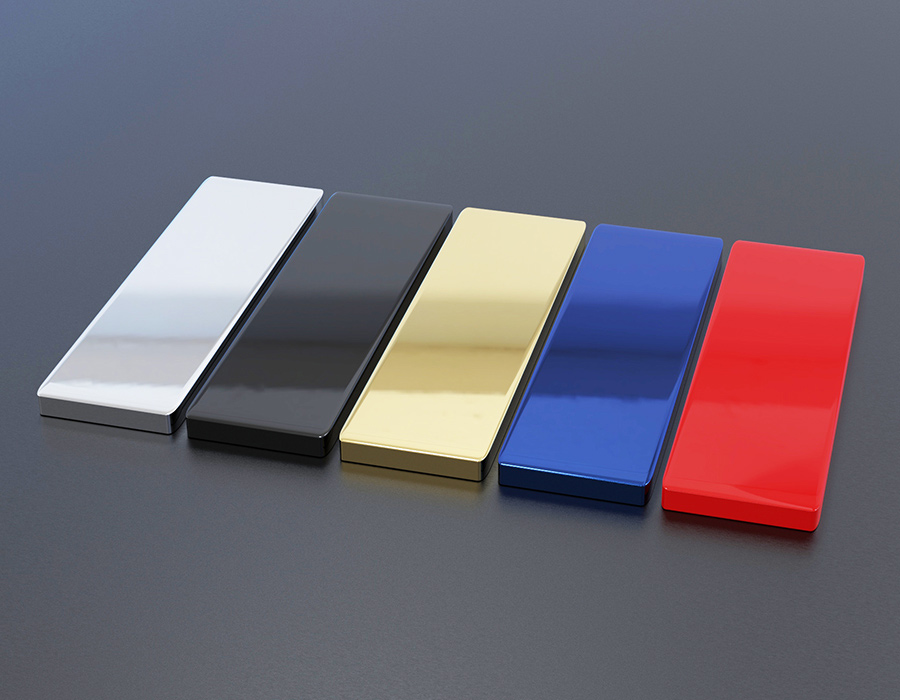

Chihenghardware specializes in manufacturing both standard and custom stamped aluminum parts, encompassing a wide range of components such as connectors, bushings, panels, and more.