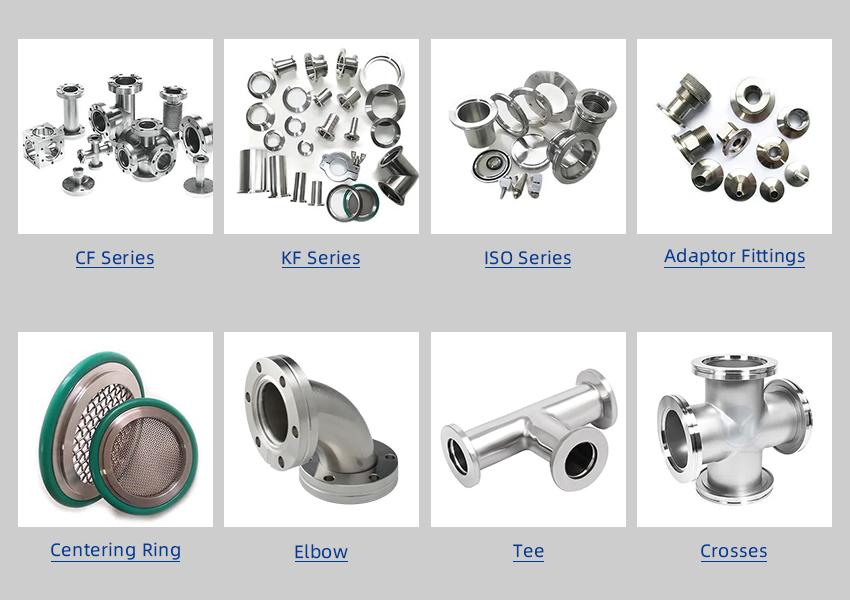

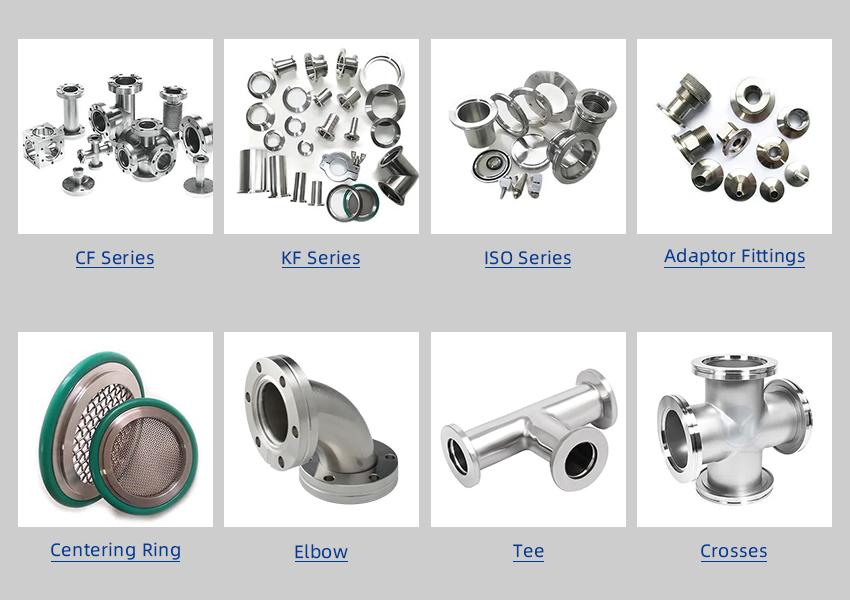

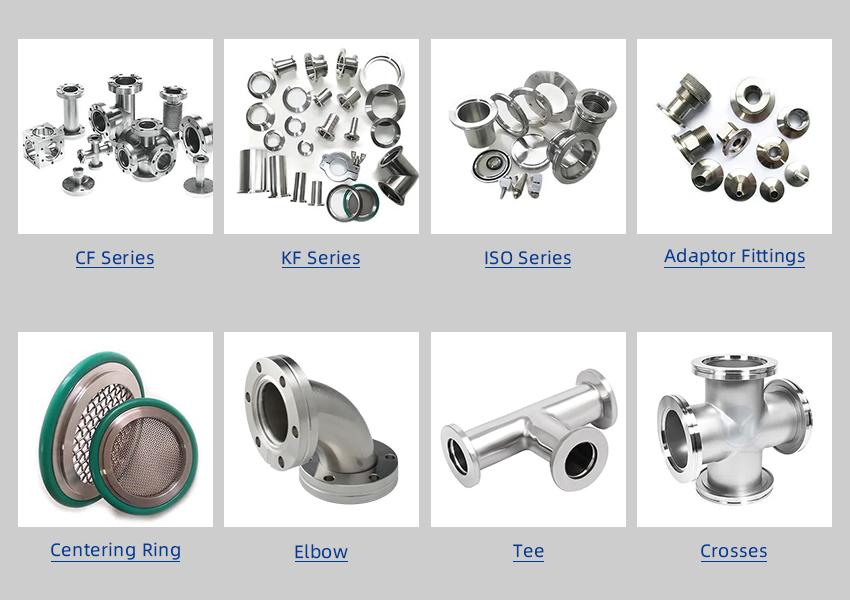

Vacuum Hardware Categories

Our Advantages in Custom CNC Machining for Vacuum COMPONENTS

As a professional manufacturer in the field of vacuum components, we offer high-quality custom CNC machining services to meet your diverse needs for precision vacuum system components.

High-Precision Vacuum Parts Machining

Utilizing advanced 5-axis CNC machining centers, we achieve ultra-high precision machining with tolerances of ±0.005mm, ensuring stringent sealing and compatibility for vacuum products. Our equipment can handle a wide range of those machining needs, from small precision parts to large vacuum chambers.

Professional Vacuum System Components Machining Solutions

We provide comprehensive custom machining solutions for vacuum system components, from design optimization to final delivery, meeting the demands of complex vacuum applications.

Custom Vacuum Chamber Machining

We specialize in machining vacuum chambers of various sizes and shapes, including rectangular, cylindrical, and custom-designed vacuum chambers, ensuring high vacuum performance and precise interface compatibility. Our vacuum components chamber machining services include internal surface treatments, multi-angle machining, and precision assembly.

Precision Manufacturing of Flanges and Connectors

We produce CF, KF, ISO, and other international-standard vacuum flanges and custom connectors, offering high-precision sealing surface machining and surface treatments to ensure perfect connectivity and sealing performance for vacuum system components.

Precision Machining of Sealing Components

We provide high-precision machining for various vacuum sealing components, including metal sealing rings, sealing flanges, and specialized sealing structures. Advanced surface treatment technologies ensure high-performance sealing and long-term reliability for vacuum hardware systems.

Pump and Valve Component Manufacturing

We specialize in machining critical components for vacuum pumps and valves, including valve seats, valve bodies, rotors, and stators, delivering precision manufacturing services for essential vacuum system components.

Vacuum System Parts Applications

Our vacuum system components are widely used across high-tech industries, providing reliable vacuum solutions for diverse applications.

Semiconductor Manufacturing Equipment

We supply high-purity, high-precision machining vacuum items for the semiconductor industry, including components for thin-film deposition systems, plasma etching systems, and ion implantation machines, meeting stringent ultra-high vacuum and cleanliness requirements.

Our custom vacuum system components are designed to withstand high-temperature, highly corrosive environments while adhering to industry-standard particle control requirements.

Scientific Research Instruments

We provide customized solutions for research institutions, including components for mass spectrometers, electron microscopes, particle accelerators, and material analysis equipment.

Our vacuum system components meet the stringent requirements of ultra-high vacuum, low leak rates, and special material compatibility, supporting advancements in cutting-edge scientific research.

Aerospace Vacuum Systems

We deliver highly reliable vacuum system parts for the aerospace industry, including satellite test chambers, space environment simulators, and propulsion system components, meeting rigorous aerospace-grade quality and long-term stability standards.

Our custom vacuum system components use specialized materials and processes to withstand extreme temperature variations and radiation environments, ensuring reliable performance in space conditions.

Medical Equipment Vacuum Components

We provide FDA-compliant hardware for the medical industry, including components for medical sterilization equipment, freeze-drying systems, and medical imaging devices, ensuring safety and reliability.

Our vacuum system components use biocompatible materials and oil-free designs to meet stringent cleanliness and stability requirements in medical applications.

Custom CNC Machining Process

We follow a systematic process to ensure every vacuum parts and accessories product meets customer expectations and industry standards.

Requirements Analysis and Design Optimization

Our engineering team collaborates closely with clients to understand the application environment and performance requirements, offering design optimization suggestions to ensure functionality and manufacturability.

Material Selection and Process Planning

Based on the specific needs of vacuum system components, we select the most suitable materials and machining processes, creating detailed production plans, including machining paths, fixture designs, and surface treatment solutions.

Precision CNC Machining and Surface Treatment

Using advanced CNC equipment, we achieve high-precision machining for complex parts geometries and dimensions, complemented by professional surface treatments such as electropolishing, anodizing, or specialized coatings.

Quality Inspection and Vacuum Performance Testing

Every vacuum system component undergoes rigorous quality inspections, including dimensional measurements, surface roughness checks, and vacuum sealing tests, ensuring compliance with technical specifications and vacuum performance requirements.

Clean Packaging and Secure Delivery

We perform professional cleaning per vacuum-grade standards and use dust-proof, anti-static packaging materials to ensure products remains uncontaminated and undamaged during transport, guaranteeing safe delivery to clients.

Customer Feedback on Our Vacuum Hardware Machining

Real feedback from global clients highlights our expertise in vacuum system components.

"As a semiconductor equipment manufacturer, we have extremely high requirements for the precision and cleanliness. Chiheng company consistently delivers top-quality components, enhancing our equipment performance and reliability."

— Director Zhang, Semiconductor Equipment Manufacturing Company

"We’ve partnered with them for five years, and their parts for vacuum customization capabilities and response speed are why we keep choosing them. Even for the most complex vacuum component needs, they deliver high-quality results."

— Manager Daniel, Medical Equipment Manufacturing Company