CNC Machined Metal Components Examples

Looking for custom metal CNC machining with tight tolerances and guaranteed precision? We specialize in producing complex, high-accuracy metal components tailored to your exact specifications.

✅ Precision You Can Count On

Using advanced CNC mill-turn technology, we deliver outstanding dimensional accuracy with tolerances ranging from ±0.01mm to ±0.005mm, ensuring every part meets your critical performance requirements.

✅ Advanced Equipment & Quality Control

Our shop is equipped with state-of-the-art CNC machines, comprehensive cutting tools, and high-resolution measuring systems — all engineered to guarantee repeatability and superior surface finishes for your custom metal parts.

✅ Ideal for Prototypes & Production Runs

Whether you're building a single prototype or need reliable production for thousands of parts, our custom metal machining services are designed to scale with your needs — without compromising precision or lead time.

Metal Material Options for CNC Milling and Lathe Turning

-

Surface FinishEnhance your parts with Chiheng's diverse surface finishing options. Our extensive range of over 10 finishes, including bead blasting, anodizing, chroming, and powder coating, allows you to tailor the appearance and performance of your components. Whether you need a corrosion-resistant finish, a visually appealing aesthetic, or a specific functional coating, we have the solution to meet your exact requirements.

Surface FinishEnhance your parts with Chiheng's diverse surface finishing options. Our extensive range of over 10 finishes, including bead blasting, anodizing, chroming, and powder coating, allows you to tailor the appearance and performance of your components. Whether you need a corrosion-resistant finish, a visually appealing aesthetic, or a specific functional coating, we have the solution to meet your exact requirements.

Custom metal parts in 7 days

Quotation and Production Process

Trusted By World-Wide Companies

Metal CNC Center

Chiheng metal fabrication centers are versatile powerhouses that excel at multi-operation processing, including advanced 5-axis machining and multi-axis simultaneous machines. These latest generation fabrication facilities integrate qualified CNC turn-mill centers, plasma cutters, and robotic welding systems, offering unparalleled flexibility in metalworking. By combining diverse capabilities such as precision cutting, forming, and welding on a single platform, these multitasking setups significantly reduce production times and enhance overall efficiency.| CNC Equipments | ||||

|---|---|---|---|---|

| Equipment | Quantity | Brand | Max Part Size | |

| 3-Axis CNC | 50 | FANUC-A-D14MIA | 1500 x 800MM | |

| 4-Axis CNC | 10 | - | D600 x L1200MM | |

| CNC Lathe | 35 | Tsugami | D300 x L1200MM | |

| Lathe-Mill Center | 3 | Tsugami | D300 x L1200MM | |

| CNC Swiss Type Automatic Lathe | 5 | Tsugami | D30 x L500MM | |

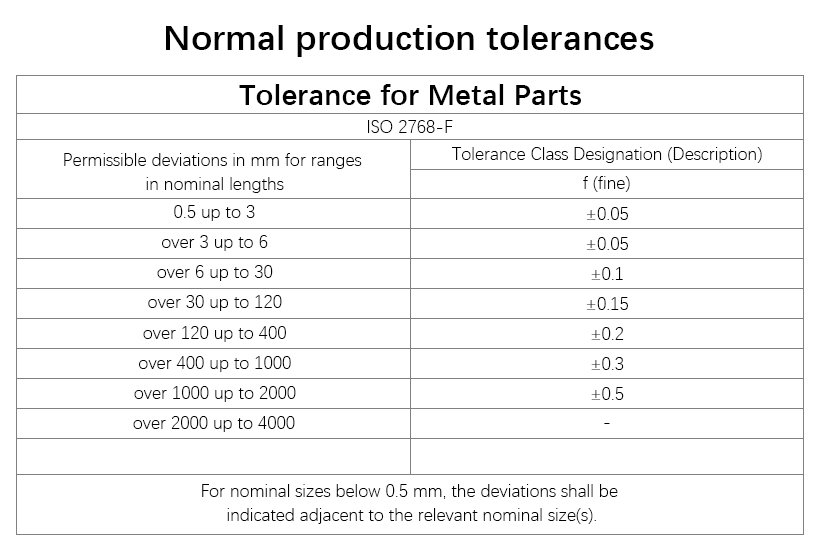

Parts Tolerances for Metal

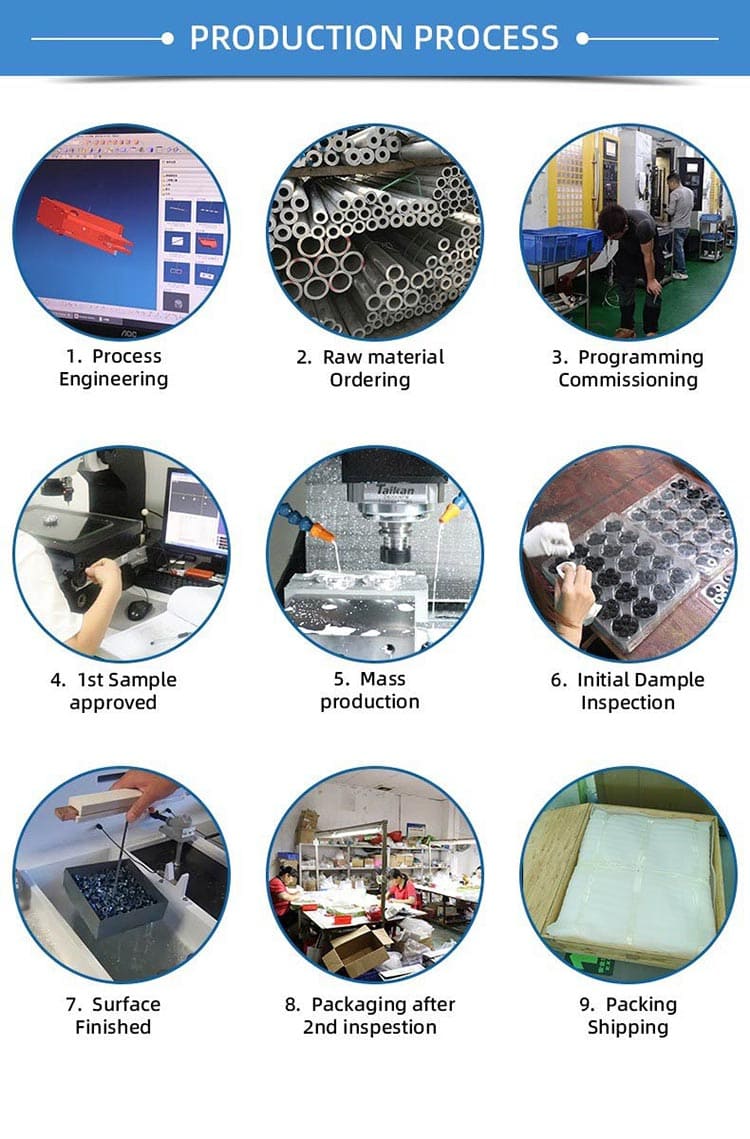

Metal Machining Processing Workflow

Chiheng has a rigorous technological process for producing high-quality molds, CNC machining parts, and samples. The process involves several key stages, including programming, raw material selection, CNC machining, quality detection, surface treatment, retesting, packaging, and transportation. This multi-step approach ensures that products meet strict quality standards throughout the production process. The company also emphasizes quality control from IQC to OQC, further demonstrating their commitment to producing reliable and affordable products.

Chiheng has a wide range of shipping options available through various carriers. This includes major international shipping companies like CMA CGM, DHL, FedEx, Maersk, APL, OOCL, UPS, TNT, Evergreen Line, MYANG MING, and EMS. This suggests that Chiheng is able to efficiently deliver their products to customers worldwide, ensuring timely and reliable shipping services.

Our dedicated team of machinists and engineers focuses on refining the CNC machining process, from fine-tuning settings to choosing the right tools and optimizing toolpaths. We also prioritize ongoing education and process enhancement, keeping our team updated with the latest CNC machining innovations and best practices.

Why Choose Chihenghardware?

-

•

Fast Quotes: Upload CAD file here to get quote and lead time in 12 hours.

-

•

Full Services: We carry full spectrum of machining services from rapid prototype, surface finish to assembly, from small batch to effective mass production.

-

•

Manufacturing Capabilities: Stamping, Bending, Metal cutting, Extrusion, Die casting, Plastic Injection.

-

•

Reduced Waiting Time: Experience a 50% reduction in your waiting period for quicker turnarounds. 3-5 standard shipping promised.

-

•

Precision Tolerance: We deliver precision with a tolerance of ±0.0002 inches (5μm).

-

•

Advanced Equipment: Over 100+ professional pieces of equipment to ensure top-quality production.

-

•

ISO 9001 Certified: Quality you can trust, backed by ISO 9001 certification with comprehensive material certification.