Essential Wind Turbine Parts: Blades and Beyond

Products: Turbine BladesMaterial: aluminum alloy/stainless steel/other alloy tool steel

Tolerance: ISO-2768-F

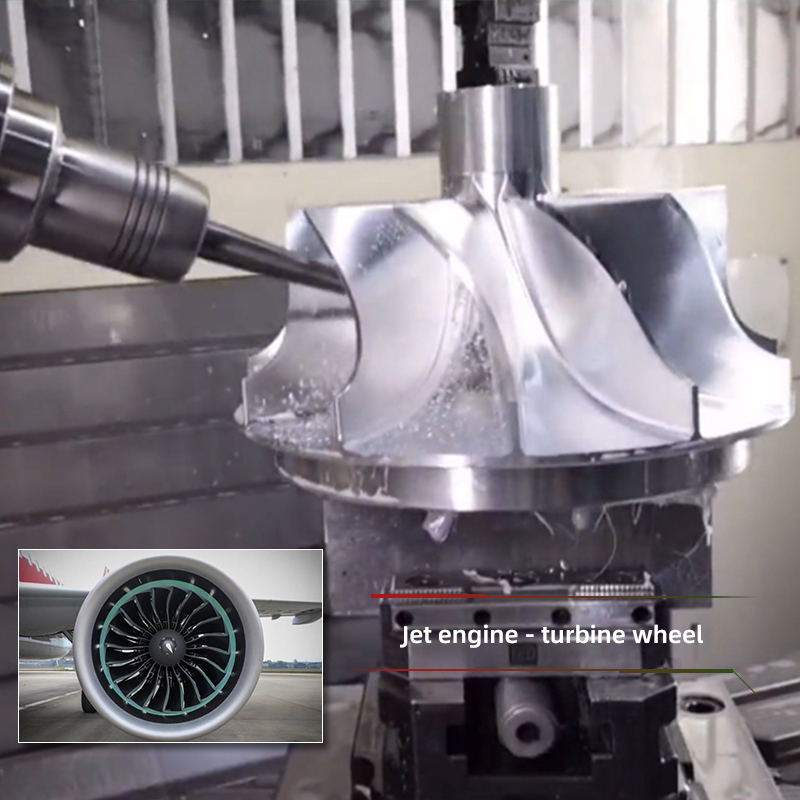

Process: CNC machining (Five-axis CNC machining)

Wind Turbine: Essential Components for Renewable Energy Generation

Wind turbine parts form the foundation of modern renewable energy systems, with the most critical components being the precisely engineered wind turbine blades that capture kinetic energy from moving air. These specialized structural parts must withstand extreme environmental conditions while maximizing energy conversion efficiency. The aerodynamic design of wind turbine blades plays a crucial role in determining overall system performance, with materials selection being equally important. Modern wind turbine blades materials include advanced composites, high-temperature alloys, and specialized coatings that ensure durability and optimal performance. Understanding the intricate engineering behind wind turbine components requires examining how these components work together in harmony. The turbine blades, often manufactured using five-axis CNC machining, represent a triumph of precision engineering where material science meets aerodynamic principles to create sustainable energy solutions for our planet's future.

Wind Turbine Blades: Design and Functionality

Wind turbine blades represent a marvel of engineering design, carefully crafted to extract maximum energy from moving air. Their aerodynamic profiles are the result of decades of research and development aimed at optimizing efficiency across varying wind conditions.

The design of wind turbine blades follows principles similar to aircraft wings, using airfoil shapes that create differential pressure as wind passes over them. This pressure difference generates lift forces that cause the rotor to turn. Modern blade designs incorporate sophisticated twist and taper along their length to accommodate the different relative wind speeds experienced from hub to tip.

The functionality of these blades extends beyond simple energy capture. Wind turbine blades generally bear high working stress and the changes of stress are frequent and severe. In addition, there are corrosion and wear problems, which have very strict requirements on working conditions. These blades must be engineered to maintain structural integrity under fluctuating loads while minimizing weight. Their design must also account for noise reduction, ice formation resistance, and lightning protection—all critical considerations for long-term operation.

In order to improve the efficiency of the turbine, the surface shape of the turbine blade is usually designed as a twisted surface with variable cross-section, making the shape quite complex. This intricate design is not just for show—it maximizes efficiency through precision engineering. The precise geometric modeling of turbine blades has become a necessary prerequisite for turbine machining. The essence of this geometric modeling is finding mathematical methods to describe the blade surface that effectively meet the requirements of shape representation and geometric design while facilitating the exchange of shape information and product data.

Wind turbine blades typically have a lifespan of 20-25 years, during which they will rotate millions of times while withstanding everything from gentle breezes to powerful storms. Their curved, twisted surface designs help maximize energy capture even during low wind conditions, demonstrating the incredible precision required in their manufacturing.

Common Turbine Blades Materials Explained

The materials used in wind turbine blades have evolved significantly as the industry has matured. Each material choice represents a careful balance between strength, weight, durability, and cost-effectiveness:

Fiber-Reinforced Composites: The majority of modern wind turbine blades utilize fiberglass-reinforced polymers (GRP) or carbon fiber-reinforced polymers (CFRP). These composites offer an excellent strength-to-weight ratio, with fiberglass providing cost efficiency and carbon fiber delivering superior performance for larger turbines. The polymer matrices—typically epoxy resins—bind these fibers together while providing resistance to environmental degradation.

High-Temperature Alloys: For specialized applications or critical connection points, high-temperature alloys are employed. We work with a variety of alloys, including aluminum, stainless steel, and other specialized alloy tool steels. In industrial and aerospace turbines, these high-temperature alloy materials possess exceptional heat resistance, providing a solid foundation for the blades and maintaining stability under extreme conditions. Even in wind applications, specialized metals are used at critical stress points.

Titanium Turbine Blades: For particularly demanding applications, titanium alloys may be used. These blades are often forged with high-temperature alloys to maintain stability under extreme conditions. Five-axis CNC machining creates these turbine blades with incredibly tight tolerances, adhering to ISO-2768-F standards to ensure perfect precision.

Protective Coatings: The external surfaces of wind turbine blades receive specialized protective coatings that serve multiple functions. These include erosion-resistant layers to protect against rain, dust, and debris; hydrophobic coatings to prevent ice buildup; and UV-resistant finishes to prevent polymer degradation from sunlight exposure. In gas turbine applications, thermal barrier coatings protect the blades from overheating.

Core Materials: Many wind turbine blades incorporate lightweight core materials such as balsa wood, PVC foam, or honeycomb structures between composite layers. These materials increase the blade's rigidity while minimizing weight, allowing for longer blade designs without excessive structural mass.

The ongoing development of wind turbine blades materials focuses on recyclability and sustainability, as the industry works to address end-of-life considerations for these massive components. Researchers are exploring bio-based resins and natural fibers as environmentally friendly alternatives to conventional materials.

How Blades Interact With Other Wind Turbine Parts

Wind turbine blades function as part of an integrated mechanical system, with their performance directly affecting and being affected by numerous other wind turbine parts. This complex interrelationship demonstrates why blades cannot be designed in isolation but must be engineered as elements of a complete system.

- • Rotor Hub Connection: The blade root connects to the rotor hub through precision-engineered bolt assemblies or specialized connection systems. This interface must transfer enormous loads while allowing for pitch adjustment—the ability to rotate each blade to optimize angle relative to the wind. The hub connection represents one of the most stress-intensive areas in the entire turbine system.

- • Pitch Control System: Modern wind turbines employ sophisticated pitch control mechanisms that adjust blade angles in real-time to maximize energy capture and protect the system during high winds. This interaction between the blades and pitch control actuators requires precise engineering to ensure smooth operation without introducing vibration or fatigue stresses.

- • Main Shaft and Gearbox: As the blades capture wind energy and rotate, they transfer torque through the main shaft to the gearbox. The rotational characteristics of the blades—including weight distribution, balance, and aerodynamic performance—directly impact the loads experienced by these downstream components. Properly designed blades help minimize harmful vibrations and irregular forces that could damage the drivetrain.

- • Generator System: The ultimate purpose of wind turbine blades is to drive the generator that produces electricity. The blades must maintain optimal rotational speeds that correspond to the generator's design parameters. Too slow, and power production is inefficient; too fast, and both mechanical and electrical systems risk damage.

- • Tower and Foundation: The dynamic forces generated by rotating blades—including thrust, gravitational loads, and gyroscopic effects—must all be supported by the tower and foundation. Blade design directly influences these loads, making the entire structural system interdependent. Modern blade designs incorporate load-shedding features that help protect the entire turbine structure during extreme weather events.

- • Control and Monitoring Systems: Advanced sensors embedded within or mounted on wind turbine blades provide real-time data on stress, temperature, vibration, and deformation. This information feeds into the turbine's control systems, allowing for predictive maintenance and performance optimization. The integration of these monitoring systems represents a growing trend toward "smart blades" that can adapt to changing conditions.

Wind Turbine Machining Process and Cooling Technologies

The manufacturing of wind turbine blades requires exceptional precision and advanced technologies. The processing precision required for these blades is very high due to their complex geometry and critical operating conditions. Five-axis CNC machining is typically employed to achieve the necessary precision for these complex shapes, particularly for metal components and connection points.

Turbines that operate in high-temperature environments, such as gas turbines in aerospace applications, face additional challenges. You might wonder, "How do these blades survive such harsh environments?" Several innovative cooling techniques are employed:

- • Internal Airflow Cooling: Channels designed within the blade allow cooling air to flow through the internal structure, carrying away heat from the core of the blade.

- • Boundary Layer Cooling: Small holes or slots in the blade surface release cooling air, creating a protective layer between the hot external gases and the blade material.

- • Thermal Barrier Coatings: Specialized ceramic coatings applied to blade surfaces provide insulation, reducing the temperature experienced by the underlying metal. These methods help protect the blades from overheating, ensuring reliable operation even in the most demanding conditions.

Challenges and Solutions in Turbine Blade Design

In demanding operating environments, turbine blades endure significant mechanical stress and temperature variations. To address these challenges, engineers have employed a series of innovative methods:

Material Innovation: The use of high-temperature alloy forging materials enables blades to maintain stability under extreme conditions, resist corrosion, and combat fatigue. These materials possess exceptional resistance to environmental stressors, providing a solid foundation for the blades.

Cooling Techniques: For gas turbine applications, cooling is crucial to maintaining blade stability. Different cooling methods, such as those mentioned above, are applied to control temperature distribution and prevent overheating.

Vibration Control: Intense vibration and resonance can lead to metal fatigue, which is the leading cause of engine failure in turbines. Therefore, engineers use methods like friction dampers to mitigate vibration-induced damage to the blades, extending their lifespan.

Even with the best design and manufacturing, turbine blading faces ongoing challenges. The incorporation of friction dampers into turbine blade designs reduces the risk of damage and helps extend the operational life of these critical components.

Conclusion

Wind turbine parts, particularly the blades, represent an extraordinary convergence of material science, aerodynamic principles, and precision engineering. Whether used in renewable energy generation or aerospace applications, turbine blades must overcome significant challenges to deliver reliable performance under demanding conditions. Through continuous innovation in materials, design, and manufacturing processes, these essential components have evolved to become more efficient, durable, and environmentally sustainable.

As renewable energy technologies continue to advance, the ongoing development of wind turbine parts will play a crucial role in our transition to cleaner energy sources. The lessons learned from aerospace and industrial turbine applications continue to inform and enhance the design of wind turbine blades, creating a fascinating crossover between these engineering disciplines. Understanding the complex interplay between materials, design, and function helps us appreciate the remarkable technology that quietly turns in the wind, generating clean electricity for our modern world.

![Aluminum 6061 vs 6063: Differences for CNC Machining Applications [2025 Guide] Aluminum 6061 vs 6063: Differences for CNC Machining Applications [2025 Guide]](/Uploads/news/677e3a8d147f1.jpg)